Keeping positive displacement blowers and vacuum pumps well maintained by performing small repairs can extend the life of both pieces of equipment. But as they age and corrosion occurs from moisture inside the inlet and discharge silencers, both will eventually need to be replaced. When the time comes to replace a bare blower or vacuum pump, it’s smart to consider replacing the whole package.

Continue readingAir Compressor Troubleshooting Guide

When an air compressor goes down, productivity can immediately slow or stop. Fortunately, there are some things you can check yourself to see if you’re facing a major compressor issue or something that can quickly be resolved.

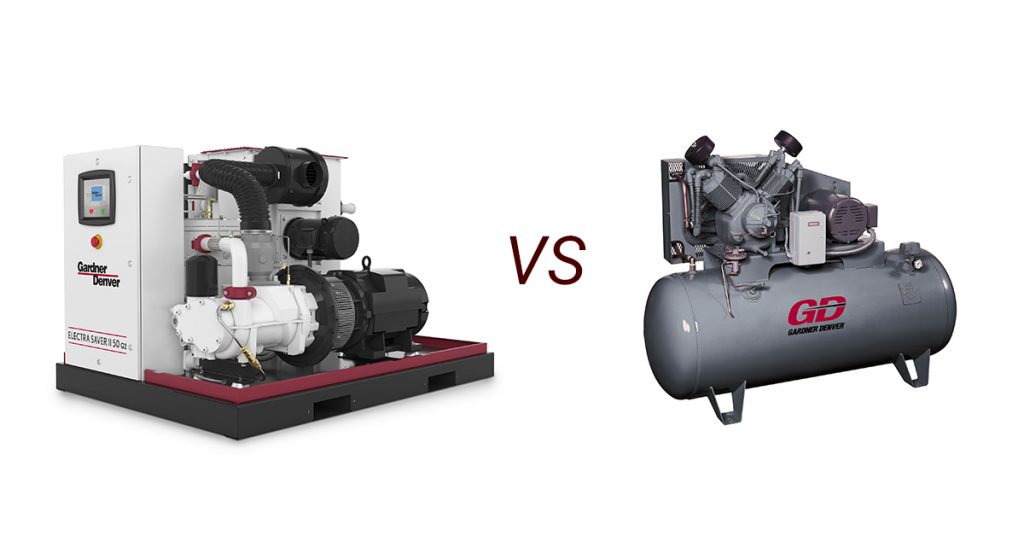

Continue readingRotary Screw vs. Reciprocating Air Compressors

When deciding on the right air compressor for your business, it’s important to distinguish between the two main types available: the rotary screw compressor and the reciprocating/piston compressor. The first notable difference is in their operation. Rotary compressors have two screws that turn in opposite directions, trapping the air between them causing compression. Reciprocating compressors use pistons that move up and down to compress the air inside the cylinder. Although most companies have relied on the uses of reciprocating air compressors and the traditional piston model, comparing the maintenance costs, required application and individual features of both types can help you determine what’s best to help your productivity and bottom line.

Continue reading