The main purpose of an air compressor system audit is to provide a comprehensive evaluation of current case operating practices and system performance from the perspective of the system’s supply side. The study and analysis are based on measurement and profiling of the production and process demand. Data is compiled and used to model current case operating costs as well as potential solution performance and the resulting cost of improvements to determine their financial feasibility.

Data Collection

The air audit evaluation is conducted with the intent to gather as much real-time data as possible. Flow (scfm), pressure (psi) and power (kW) are measured and data is logged using thermal mass flow transmitters, pressure transmitters and amp or kW transmitters. Transmitter output is recorded on data loggers at a specific polling rate and later downloaded to a computer for analysis and modeling.

Reporting

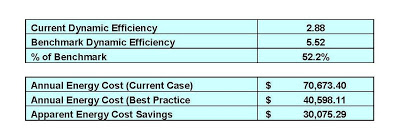

Once the data is collected, an analysis can provide the basis for power validation and solution modeling. The first report below is a tabular summary of information gathered for a system. This table provides high level attributes and the basis for improvements. Comparing both the Dynamic Efficiency (current case to benchmark) and the energy cost (current case vs. proposed) will help determine the potential and feasibility of system enhancements.

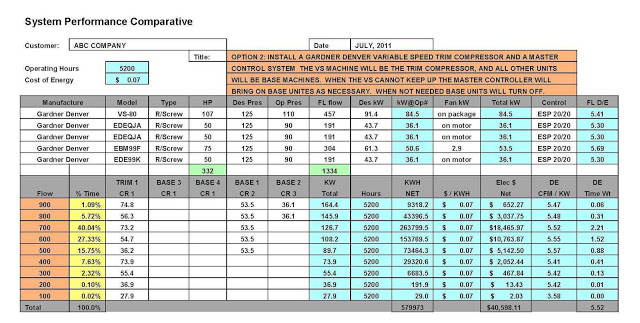

Once the high-level attributes and potential improvements have been reviewed, air audit professionals can dig a little more in depth and look at the actual options available to the customer. Each option should be compared with current case costs in a System Performance Comparative as shown below. This table documents existing equipment and recommendations for future energy savings.

Cost Analysis

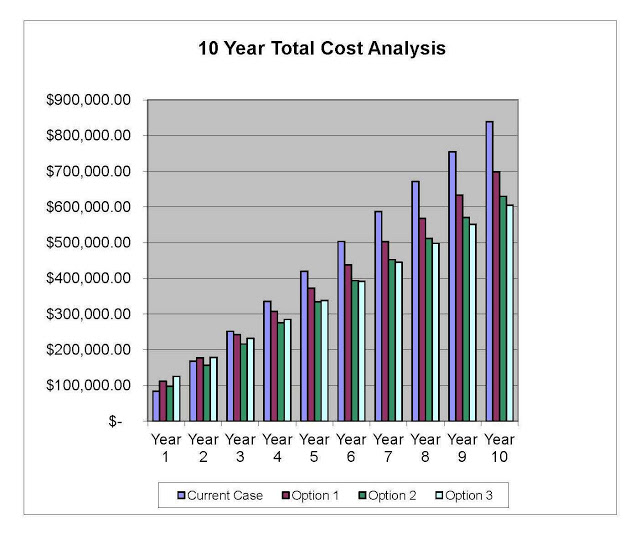

The last piece of information that really brings an air audit together is the cost analysis. What is the payback period on making any recommended changes and how much money will actually be saved over a period of time? Below is a graph of a 10 Year Total Cost Analysis for a customer who had three options based on the findings of a recent audit. This graph allows you to see not only the operating cost spread over 10 years, but also shows the payback timeframe for each option if it was to be implemented. Seeing the financial implications in this way allows you to determine if the cost savings are great enough to warrant changes, and if so, to and select the option that makes the most sense for your business.

A compressed air system audit can provide all the data and modeling that a customer needs to identify opportunities for improvements in air compressor efficiency and cost savings. The certified air compressor technicians at Lewis Systems are experienced in performing compressed air audits and providing cost saving solutions. If you have any questions about air audits or would like to speak to us about having one completed, please contact us and we’ll be happy to discuss it with you.